Design, Prevent, and Detect

Our core approach to Quality is to design quality and manufacturability into our products, using world-class equipment and processes to manufacture defect-free parts every time.

Design

We utilize a structured stage-gate product development process that follows the automotive Advanced Product Quality Planning (APQP) approach

Prevent

Our first line of defense is always the prevention of defects . In addition to deployment of all APQP tools, SHIELD counts assembly automation among our many core competencies, helping to eliminate human error. SHIELD automation includes integrated poka-yokes and automatic containment of defects.

Detect

As an added layer of security, SHIELD uses statistical process controls and intensive lot acceptance testing. 100% of retractors and buckles are functionally tested before leaving the facility.

In-House Testing Capabilities

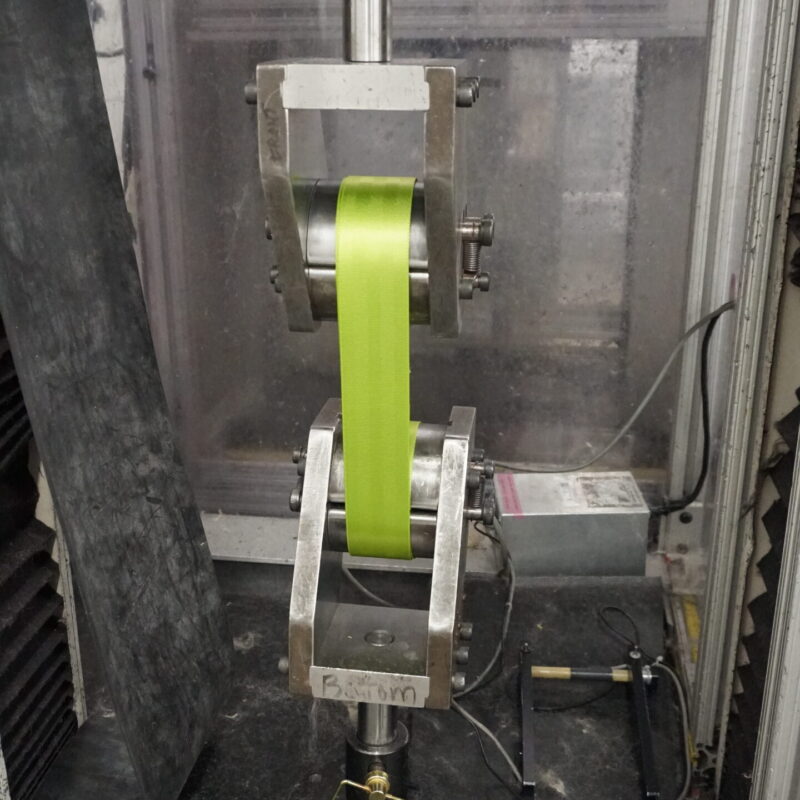

- Tensile

- Standard Cycle Durability

- Harsh Environment Cycle Durability

- Extraction and Retraction

- Micro-slip

- Release force

- Thermocycling

- Dust Exposure

- Simulated Sled Test

- Hardness Testing

- Component and Assembly Measurement

- CMM Measurement

- 2D Vision Measurement

- 3D White Light Measurement

- Electrical performance

- Salt Spray Corrosion

- Hex Bar Abrasion

- FMVSS 302 Testing

Quality Designed In

We use a stage-gate development process that helps us design in quality and manufacturability from the start.

Process Control

We monitor, control and document every step through our facility, from incoming raw materials to shipping finished product.

Testing & Inspection

We functionally test 100% of retractors and buckles that go out the door